Overview

JJR specializes in the fabrication of high-quality components for aerospace, defense, space sector, performance racing, clean tech, marine, and many other commercial industries. We have vast experience and knowledge in precision machined details, sheet metal components, formed parts, assemblies, and thermoformed plastics.

We have expertise working with numerous materials including aluminum, stainless steel, titanium, plastics, and phenolics. Our in-house design, engineering, and 3D modeling capabilities allow us to help our clients build quality products faster and more affordable, by improving the manufacturability of their parts before fabrication ever begins.

We take pride in supporting high mix, low volume runs, but can also support high volume production runs. Our standard lead time is typically 4-6 weeks, with expedited lead times as an option. We rely on our internal resources for all engineering and manufacturing operations.

We utilize local supply chains for material acquisition and outside processes. This allows us to thoroughly manage the entire build and reduce lead times for our clients.

Our reputation was built on precision and our proven track record with the products and services listed below, make JJR an ideal partner to turn your dreams and designs into a reality.

Our core capabilities include:

- Precision machined parts

- Sheet metal forming and fabrication

- Extrusion machining and forming

- Thermoformed plastics

- Multi-detail assemblies

- Tooling design and fabrication

- Engineering services

Our core services include:

- Wide range of material vendors and finish facilities

- NADCAP finish requirements

- Experienced QA team

- First article reports

- ProShop ERP

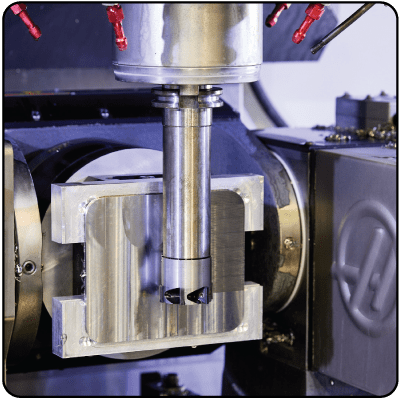

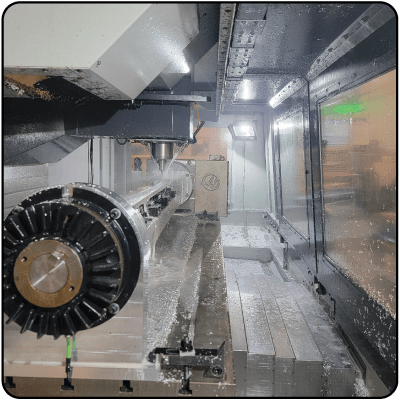

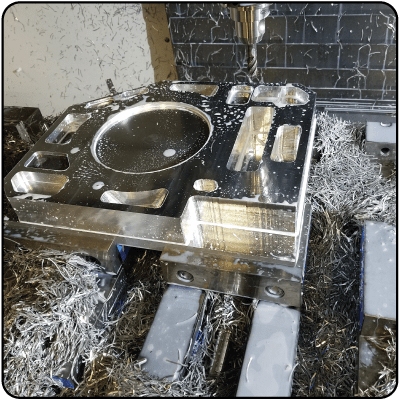

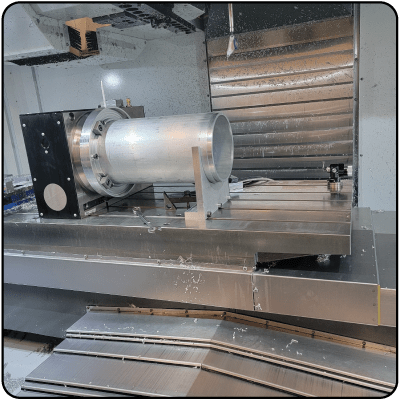

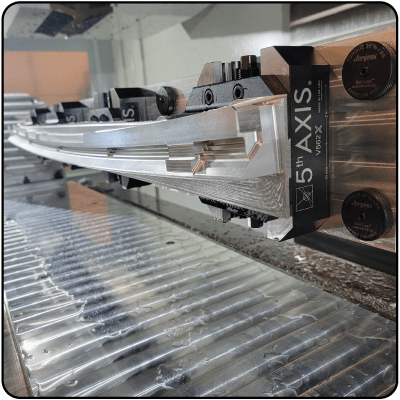

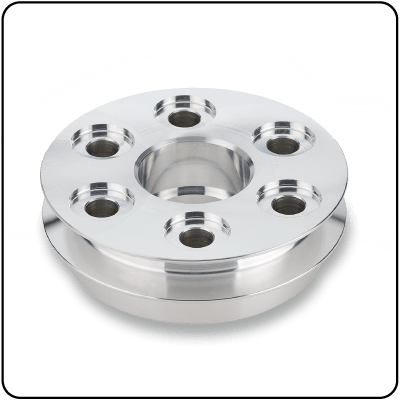

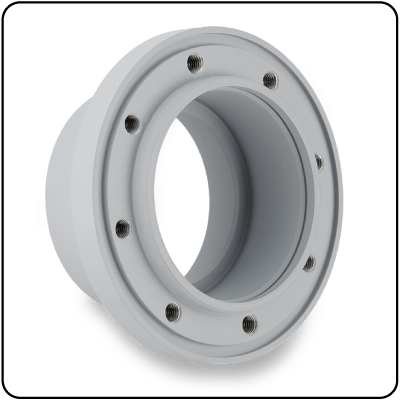

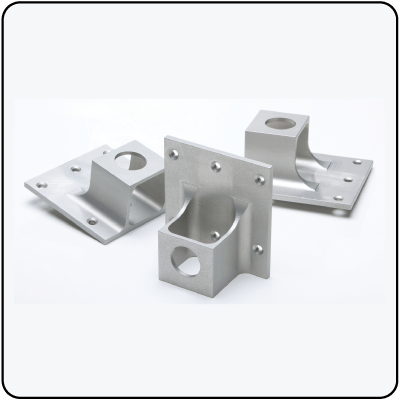

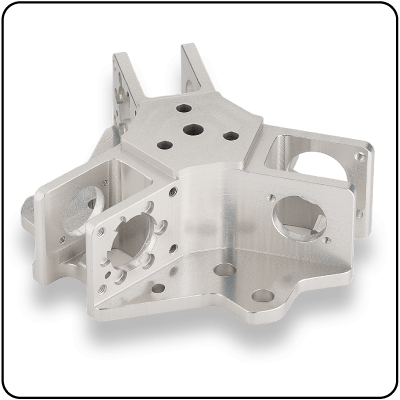

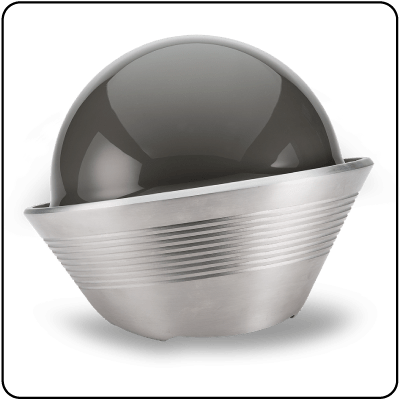

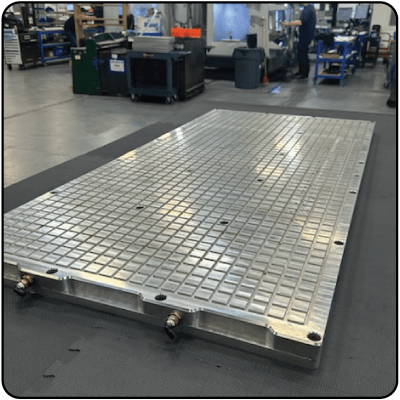

CNC Machining

JJR is constantly expanding its machining capabilities by utilizing premier programming software, state-of-the-art equipment, and highly trained machinists. Our machining capabilities range from simple 2-axis turned parts, to highly complex 5-axis milled parts. We use our vertical milling centers, mill turn lathe, and router table to produce an assortment of high accuracy machined parts and components. Using cellular work centers and our paperless ERP system, we are able to maximize production, 7-days per week to fulfill the needs of our clients.

We can support both low and high volume production using the following CNC platforms:

- 3-, 4-, and 5-axis vertical mills

- 4-axis mill turn / lathe

- Router table

- Manual mill

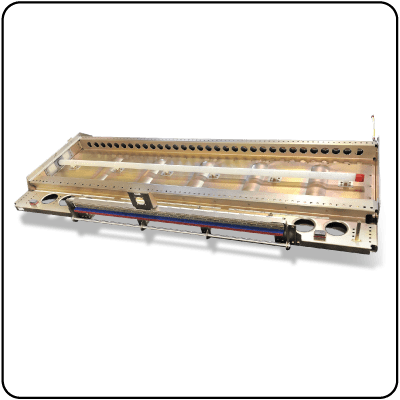

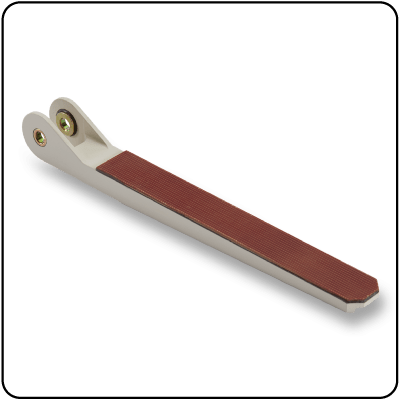

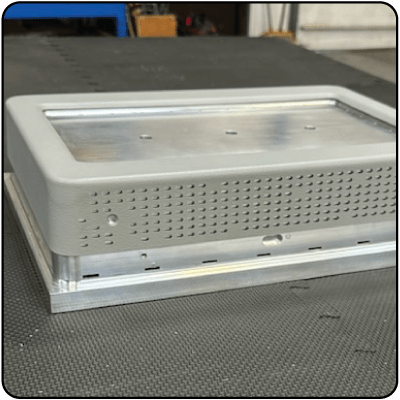

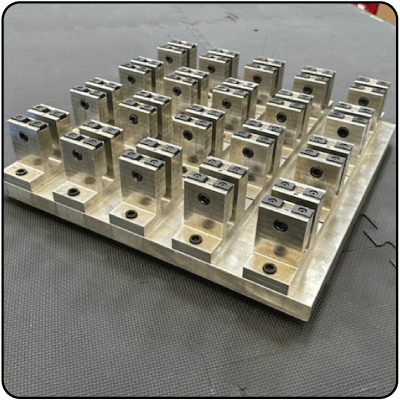

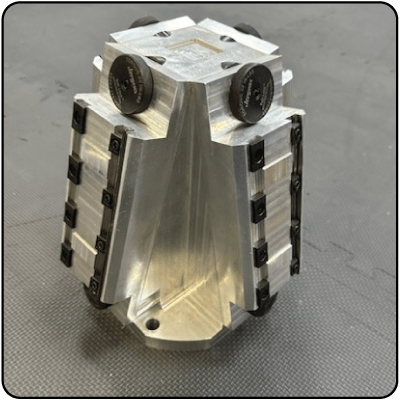

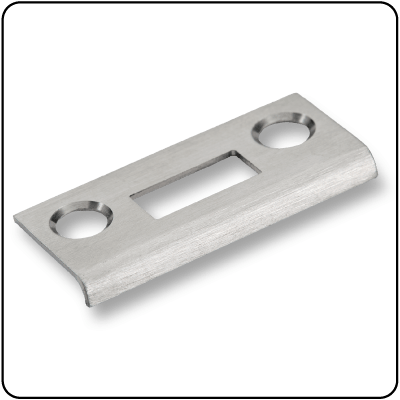

Below is a sample list of CNC parts we have made for our clients.

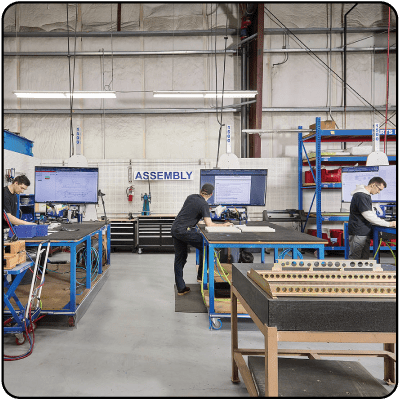

Assembly

Our assembly capabilities encompass a wide range of complex tasks, including the integration of intricate sub-assemblies, precise alignment of components, and the application of advanced bonding and fastening techniques. We possess expertise in handling a wide range of materials, including composites and high-performance alloys, while adhering to stringent quality standards and certifications. Our state-of-the-art facility and highly skilled machinists apply meticulous assembly processes, minimizing risks and maximizing efficiency to deliver high-quality and reliable components and parts to our clients.

Assembly Competencies

- Tooling and fixturing

- Drilling and reaming

- Bearing installation

- Bushings installation

- Sealant application and bonding

- Helicoils

- Nutplates

- Hi-locks

- Rivets

- Electrical bonding

- Ground studs

- Ground straps

- Multiple detail builds: up to 48”x 96”

- Conductivity/resistance testing

JJR on-hand consumables for assembly:

• BMS 5-95

• BMS 5-45

• BMS 10-11

• Alodine 600 and 1200

JJR on-hand hardware for assembly:

• Rivets

• Nutplates

• Bolts

• Washers

• Screws

• Nuts

• Helicoils

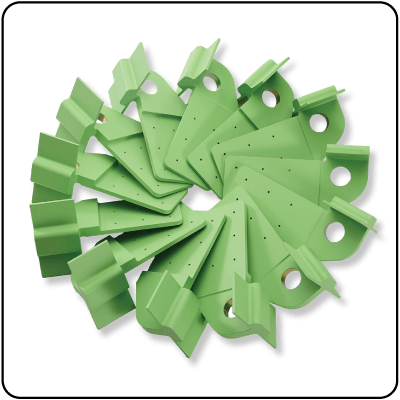

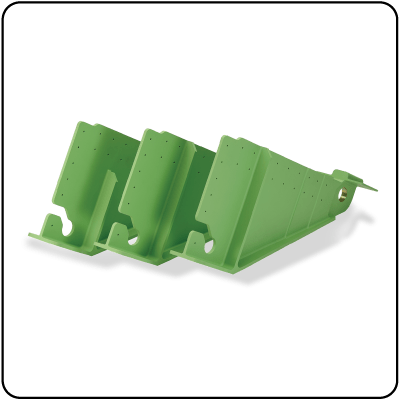

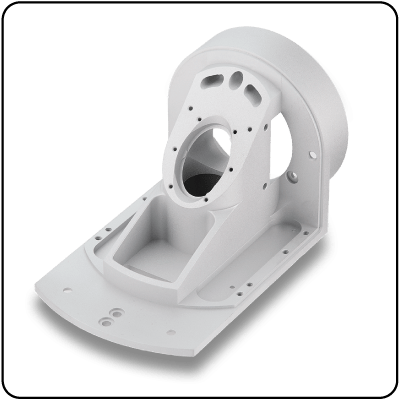

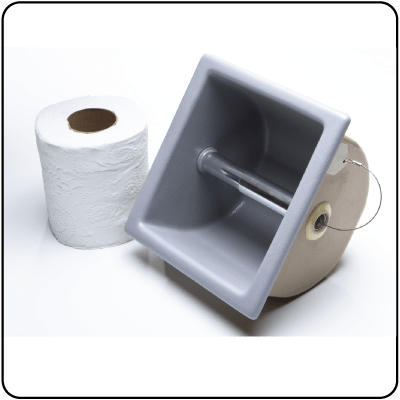

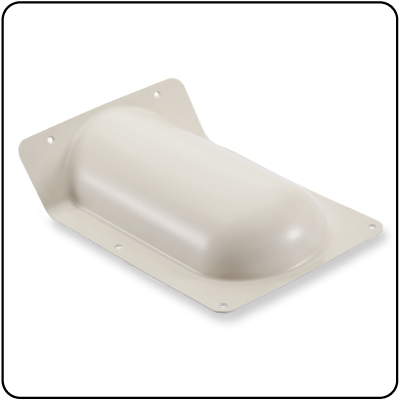

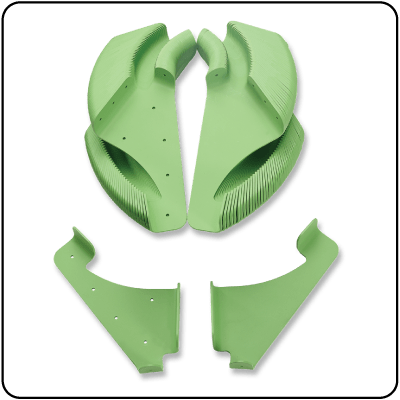

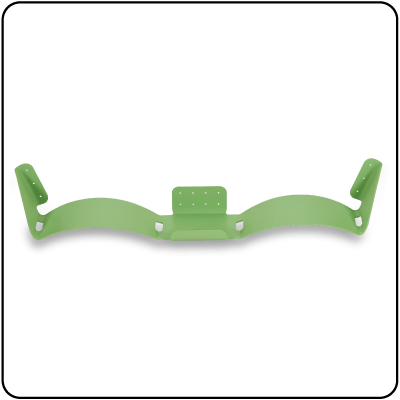

Thermoforming

Thermoforming is a versatile manufacturing process that can create a wide range of plastic parts. Our thermoforming process is extremely flexible, cost effective, and allows for a variety of applications such as prototyping, small production and large production runs. We are able to engineer and fabricate molds in-house allowing us to swiftly build your deliverable. This manufacturing method has allowed us to make everything from aerospace interior trims and shroud components, to firearm holsters. The applications are endless.

Using a variety of innovative techniques, we are able to produce extremely complex custom components. Unique features that can be added include:

• Notches

• Holes

• Slots

• Countersinks

• Multi-Plane Trimming

Thermoforming materials we work with include Kydex, Boltaron, ABS, polycarbonate, etc.

Below is a sample of thermoforming parts we have produced for our clients.

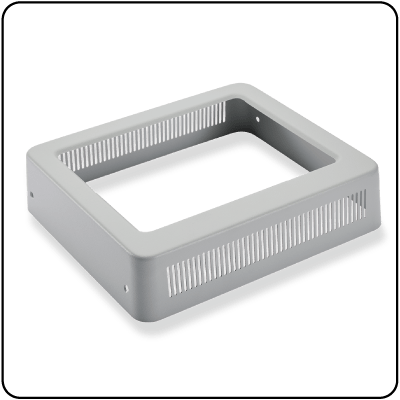

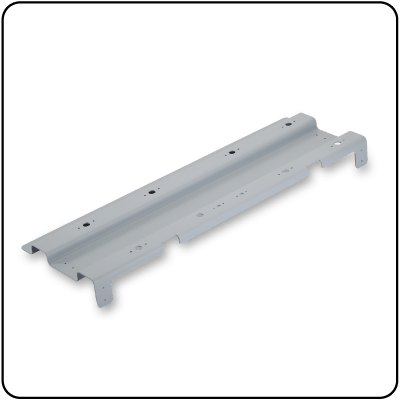

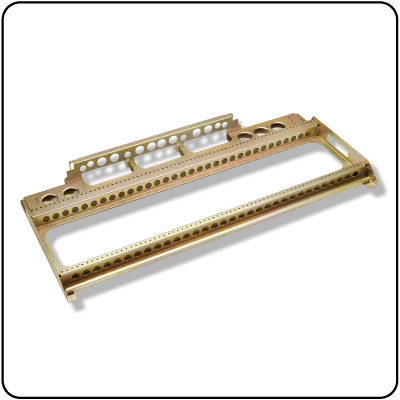

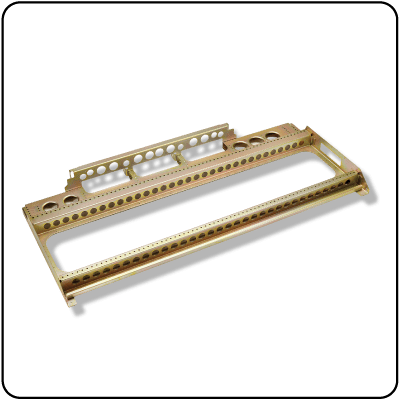

Sheet Metal Fabrication

JJR has extensive experience in sheet metal fabrication. We stay at the forefront of industry standards by utilizing the latest technology and tooling. We consistently deliver high-quality products across a wide range of part types, sizes, and materials.

- Formed sheet (up to 72” long)

- 24” max flange length

- Intricate sheet metal forming

- Brackets, covers, stands, fuel cells, kick strips, step plates, flared holes, louvers, hems, stamping, and spring clips

- Multiple detail assemblies

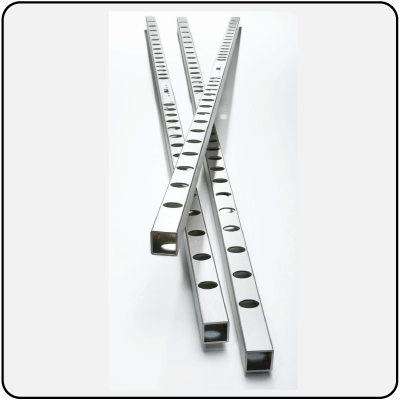

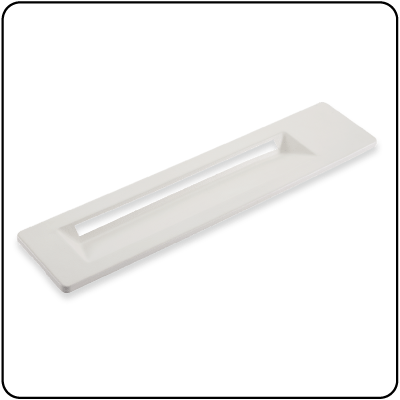

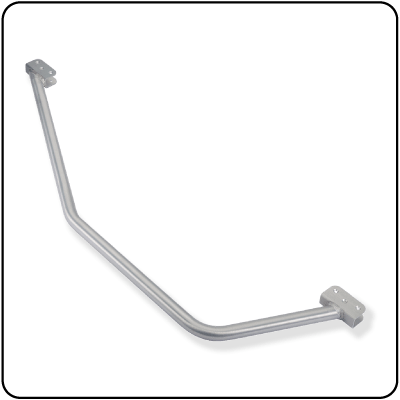

Extrusion Forming

With years of experience, JJR excels at complex forming solutions for a wide variety of extrusions. We have developed advanced processes that deliver rapid manufacturing of intricate shapes with exceptional accuracy. Our in-house engineering and toolmaking expertise ensures seamless adaptation to any new extrusion profiles.

- Curtain Rail Forming

- Various Formed Trim Extrusions

- Hand Rails

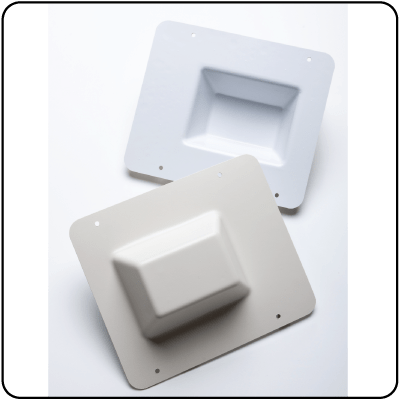

Custom Tooling

Being deeply ingrained in product assembly, JJR is a center of excellence for the manufacturing of the tooling and fixtures needed to get the job done. We’re constantly developing more intelligent ways to ease manufacturing processes for ourselves and those who work with us. Detail tooling components complement other manufacturing operations to ensure quality, repeatability, and reduce processing time. JJR engineers and manufactures the following tooling in-house.

- Locating jigs

- Fixtures (3-, 4-, and 5-axis)

- Templates

- Drill plates

- Molds

- Form fit check tools

- Press brake tooling

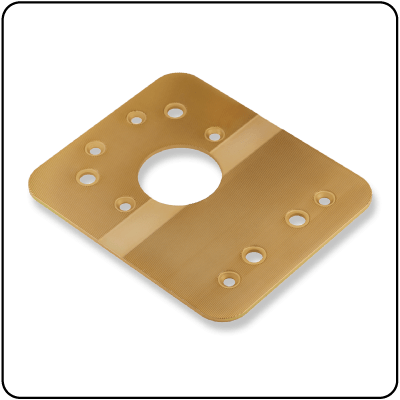

Finish and Processing

We work closely with numerous finish houses to accommodate the following finishes.

- Penetrant inspection

- Magnetic particle inspection

- Passivate

- Heat treat

- Anodize (Boric-Sulfuric, hardlube, color)

- Brush

- Chemical treat

- Bead blast

- Primers

- Paints

- Swaging

- Welding

- Brazing

- and more!

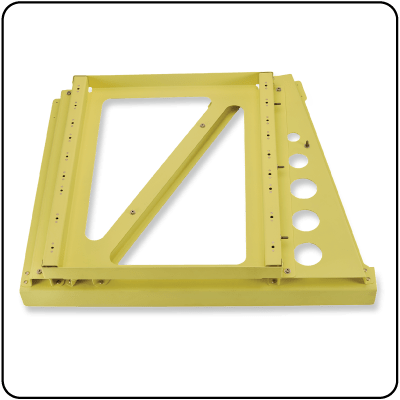

Brush finish

Yellow chemical finish

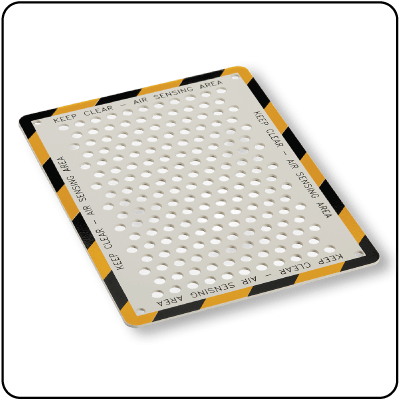

Quality Control and Assurance

Our quality assurance encompasses a comprehensive system of processes and procedures designed to ensure that all aspects of manufacturing, from design and development to production and maintenance, meet the highest standards of safety, reliability, and performance. This includes stringent inspections, rigorous testing protocols, and meticulous documentation to guarantee that every component and system functions flawlessly to meet or exceed all relevant industry regulations and certifications.

- AS9100

- Verisurf Model Based Measurement Software

- Master3DGage CMM

- Nikon comparator

What type of parts can we make?

JJR can produce a wide assortment of products that serve a variety of different markets ranging from aerospace, space sector, performance racing, clean tech, marine, and many other commercial industries. Some examples of parts we have made include:

- Fittings

- Brackets

- Stiffeners

- Clevises

- Trim

- Rods / rod ends

- Extrusions

- Tubes

- Bolts

- Lock nuts

- Latches

- Hinges

- Molds

- Jigs

- Tooling

- Broached

- Flat sheet metal

- Formed sheet metal components

Types of material we work with?

JJR can run an assortment of sheet, plate, and extrusions:

- Aluminum

- Mild steels

- Stainless steels

- Plastics (Nylon, Delrin, Kydex, UHMW, Teflon, etc)

- Phenolics

- Titanium

- Foams

- Honeycomb

- Wood

425-485-1831

19401 144th Ave NE, Building D, Woodinville, WA 98072